1. Nkenke

A na-edozi eri dị n'ime nke ebili mmiri ogologo na-eji ma họrọ ka a ga-eji mee ihenkịtị boltsna bolts na-akpọchi onwe ya, nke a na-ahazi site na atụmatụ dị iche iche na-emesi ike, yana ọdịiche dị n'etiti bolts arịlịka na nchikota nke onwe ya, a na-enyocha akụkụ nke njirimara. Nsonaazụ: Usoro nhazi nke bolt na bolt ga-enweta njirimara nhazi dị iche iche, oge mkpọchi nke yinye na-eme ka nhazi nke onwe ya na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe dị iche iche. N'ihi usoro mmegharị ahụ nkịtị, njirimara njirimara dị iche iche enwetara ga-aga n'aka nri.

2. Nyochaa nkà ihe ọmụma

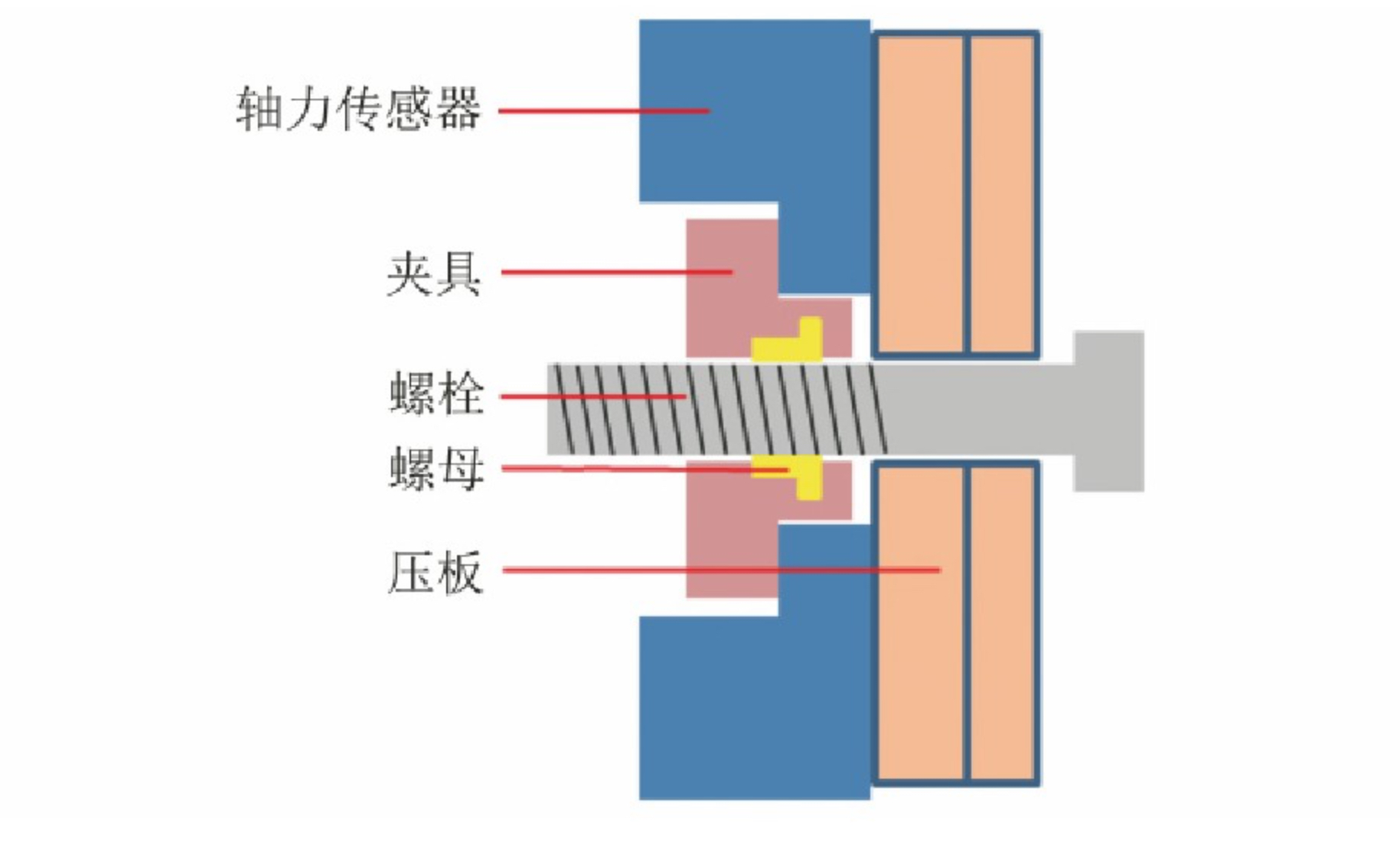

Ka ọ dị ugbu a, a na-eji usoro ultrasonic eme ihe n'ọtụtụ ebebolt axial force testnke fastening ebe nke ụgbọ ala subsystem, ya bụ, mmekọrịta e ji mara usoro (bolt calibration curve) n'etiti bolt axial ike na ultrasonic ụda oge dị iche na-enweta n'ọdịnihu, na ụdi ule nke n'ezie akụkụ subsystem a rụrụ. Enwere ike nweta ike axial nke bolt na njikọ tightening site na ultrasonically na-atụle ụda oge dị iche iche nke bolt ma na-ezo aka na nhazi nhazi. Ya mere, inweta usoro nhazi nhazi ziri ezi dị mkpa karịsịa maka izi ezi nke nsonaazụ axial Force nke bolt na mpaghara mpaghara n'ezie. Ka ọ dị ugbu a, ụzọ nnwale ultrasonic na-agụnyekarị otu usoro ebili mmiri (ya bụ usoro ogologo ogologo) yana ụzọ ntụgharị ogologo ogologo.

N'ime usoro nhazi nke bolt, enwere ọtụtụ ihe na-emetụta nsonaazụ nhazi, dị ka njigide ogologo, okpomọkụ, ọsọ nke igwe na-eme ka ọ dị ike, ngwa ngwa ngwa ngwa, wdg. Ugbu a, usoro nhazi nke na-ejikarị eme ihe bụ usoro ntụgharị ntụgharị. A na-edozi bolts na bench test bolt, nke na-achọ ka mmepụta ihe na-akwado nkwado maka ihe mmetụta axial, nke bụ efere nrụgide na ntinye eriri eriri dị n'ime. Ọrụ nke ntinye oghere eriri ime bụ iji dochie mkpụrụ mgbe niile. A na-ejikarị imewe ihe mgbochi rụrụ arụ na ebe njikọ njikọ nwere nnukwu nchekwa nchekwa nke chassis ụgbọ ala iji hụ na ntụkwasị obi nke njide ya. Otu n'ime usoro mgbochi rụrụ arụ nke a na-anakwere ugbu a bụ akị na-ekpochi onwe ya, ya bụ, mkpụrụ akụ na-ekpochi nke ọma.

Onye ode akwụkwọ na-agbaso usoro ebili mmiri ogologo wee na-eji eriri ime ime onwe ya mere onwe ya wee họrọ akị nkịtị na akị na-ekpochi onwe ya iji mee ka ihe mgbochi ahụ dị. Site na usoro dị iche iche siri ike na usoro mmezi, a na-amụ ihe dị iche n'etiti aku nkịtị na aku na-ekpochi onwe ya iji mee ka ọnyà bolt dị. Nnwale axial force fasteners ụgbọ ala na-enye ndụmọdụ ụfọdụ.

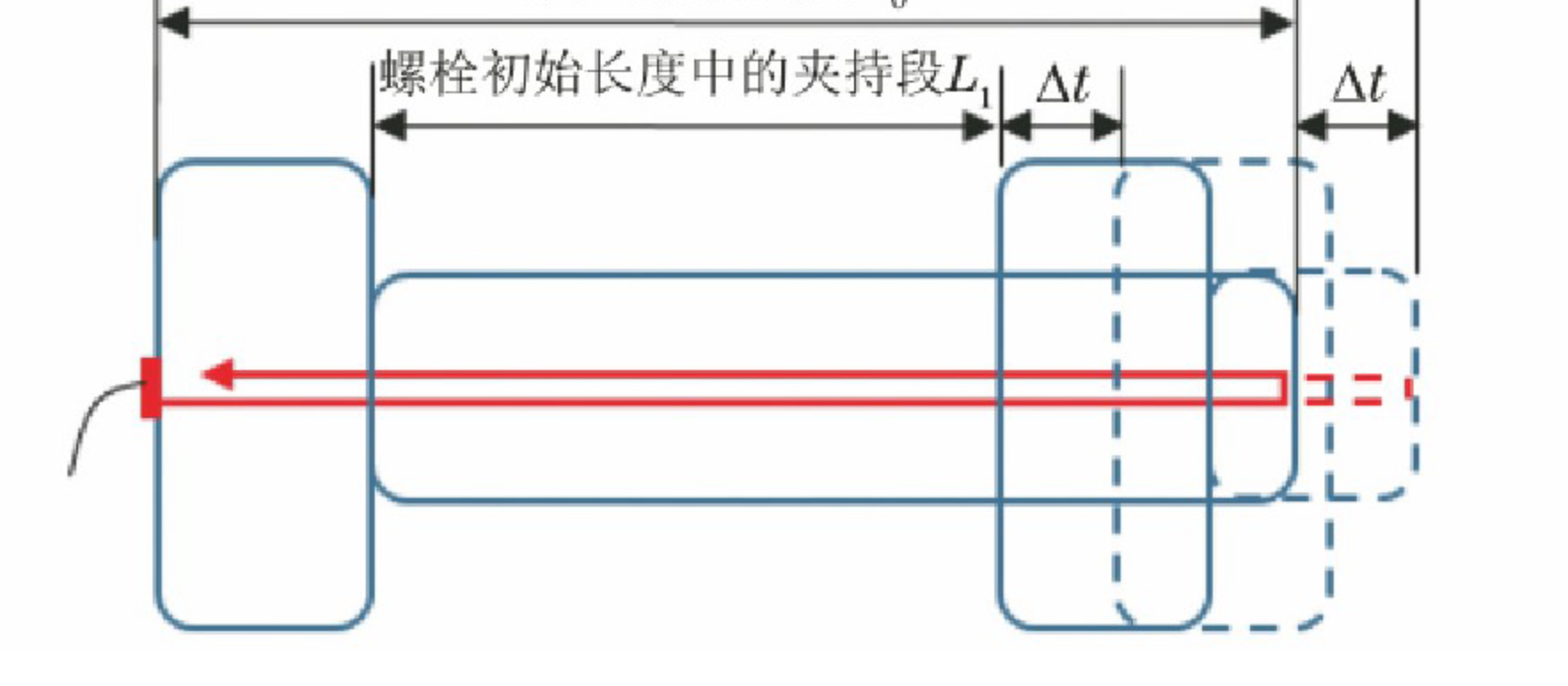

Nnwale ike axial nke bolts site na teknụzụ ultrasonic bụ usoro nnwale na-apụtaghị ìhè. Dị ka ụkpụrụ nke sonoeelasticity si dị, ọsọ nke mgbasa ụda na ihe siri ike metụtara nrụgide ahụ, ya mere enwere ike iji ultrasonic ebili mmiri nweta ike axial nke bolts [5-8]. Ihe mkpuchi ahụ ga-agbatị onwe ya n'oge usoro ịgbatị ahụ, ma n'otu oge ahụ na-emepụta nrụgide axial tensile. A ga-ebufe pulse ultrasonic site na isi nke bolt na ọdụ. N'ihi mgbanwe mberede na njupụta nke ọkara, ọ ga-alaghachi n'ụzọ mbụ, na elu nke bolt ga-enweta mgbaàmà site na piezoelectric seramiiki. oge dị iche Δt. E gosipụtara eserese schematic nke nyocha ultrasonic na eserese 1. Ogologo oge dị iche na elongation.

Nnwale ike axial nke bolts site na teknụzụ ultrasonic bụ usoro nnwale na-apụtaghị ìhè. Dị ka ụkpụrụ nke sonoeelasticity si dị, ọsọ nke mgbasa ụda na ihe siri ike metụtara nrụgide ahụ, ya mere enwere ike iji ultrasonic ebili mmiri nweta.ike axial nke bolts. Ihe mkpuchi ahụ ga-agbatị onwe ya n'oge usoro ịgbatị ahụ, ma n'otu oge ahụ na-emepụta nrụgide axial tensile. A ga-ebufe pulse ultrasonic site na isi nke bolt na ọdụ. N'ihi mgbanwe mberede na njupụta nke ọkara, ọ ga-alaghachi n'ụzọ mbụ, na elu nke bolt ga-enweta mgbaàmà site na piezoelectric seramiiki. oge dị iche Δt. E gosipụtara eserese schematic nke nyocha ultrasonic na eserese 1. Ogologo oge dị iche na elongation.

M12 mm × 1.75 mm × 100 mm na nkọwapụta nke bolts, na-eji nkịtị bolts na-edozi 5 dị otú ahụ bolts, mbụ na-eji onwe-arịlịka ule na ụdị dị iche iche nke calibration solder mado, ọ bụ artificial spiral efere ka bolt flange dabara na pịa Mgbe scanning mbụ ife (ya bụ, na-edekọ mbụ 00 N'ikuku) na 1 m. (nke a na-akpọ usoro nke m), nke ọzọ bụ iji nyocha nke mbụ ebili mmiri ma were egbe na-agbatị ya (nke a na-akpọ ụdị m usoro). Maka usoro ụdị nke abụọ), a ga-enwe ụdị ụfọdụ na usoro a (dị ka e gosiri na foto 4) 5 bụ ihe nkwụsị nkịtị na usoro nke onwe ya Usoro mgbanaka mgbe nhazi dị ka ụdị m usoro Figure 6 bụ ụdị mkpuchi onwe ya. Ọgụgụ 6 bụ klaasị na-akpọchi onwe ya. Klas I na klaasị II akụkụ. Usoro eji eme ihe nwere ike ịbụ, jiri usoro omenala nke klas arịlịka arịlịka nkịtị, otu ihe ahụ (niile na-agafe na mmalite ya na ọnụ ọgụgụ nke akụkụ na ọnụ ọgụgụ isi); igbachi ụdị index nke ụdị arịlịka (ụdị I na arịlịka akara, mkpọda nke etiti dị iche na ọnụ ọgụgụ nke isi); nweta myirịta)

Nnwale 3 bụ ịtọ ntọala Y3 nke Graph Setup na ngwanrọ nnweta data dị ka nhazi ọnọdụ okpomọkụ (iji ihe mmetụta okpomọkụ dị n'èzí), tọọ ebe dị anya nke bolt ahụ ruo 60 mm maka nhazigharị, ma dekọọ ike / axial ike / okpomọkụ na akụkụ nke akụkụ. Dị ka e gosiri na foto 8, a pụrụ ịhụ na site na nkwụsịtụ nke mkpuchi na-aga n'ihu, okpomọkụ na-arị elu na-aga n'ihu, a pụkwara iwere ọnọdụ okpomọkụ dị ka linear. Ahọpụtara ihe nlele bolt anọ ahụ maka nhazi ya na mkpụrụ na-ekpochi onwe ya. Onyonyo 9 na-egosi usoro nhazi nke bolts anọ. Enwere ike ịhụ na a na-atụgharị akụkụ anọ ahụ n'aka nri, mana ogo ntụgharị asụsụ dị iche. Tebụl 2 na-edekọ ebe dị anya na usoro nhazigharị na-atụgharị gaa n'aka nri yana mmụba okpomọkụ n'oge usoro mmechi ahụ. Enwere ike ịhụ na ogo nke usoro nhazigharị na-agbanwe gaa n'aka nri bụ n'ụzọ bụ isi na mmụba okpomọkụ.

3. Mmechi na Mkparịta ụka

A na-edobe ihe mkpuchi ahụ na-arụkọ ọrụ ọnụ nke nrụgide axial na nrụgide torsional n'oge a na-emesi ike, na ike nke abụọ ahụ na-emecha mee ka ọkpụkpụ ahụ pụta. Na nhazi nke bolt ahụ, ọ bụ naanị ike axial nke bolt ka a na-egosipụta na nhazi nhazi iji nye ike nkedo nke subsystem nke na-emechi. Enwere ike ịhụ ya site na nsonaazụ ule dị na Figure 5 na, ọ bụ ezie na ọ bụ mkpụrụ na-ekpochi onwe ya, ma ọ bụrụ na edere ogologo nke mbụ mgbe ejiri aka gbanwee bọtịnụ ahụ ruo n'ókè nke na ọ na-achọ ka ọ dabara n'elu elu nke efere nrụgide ahụ, ihe nkwụsị nke calibration na-adaba kpamkpam na nke ndị nkịtị nut. Nke a na-egosi na na steeti a, mmetụta nke ike na-ekpuchi onwe ya nke nut na-ekpuchi onwe ya bụ ihe na-adịghị mma.

Ọ bụrụ na a na-agbanye bọtịnụ ahụ ozugbo n'ime nut na-akpọchi onwe ya na egbe eletriki, usoro ahụ ga-agbanwe gaa n'aka nri n'ozuzu ya, dị ka e gosiri na Figure 6. Nke a na-egosi na nkwụsị nke onwe ya na-emetụta ụda oge dị iche iche na nhazi nhazi. Leba anya na akụkụ mbụ nke ntụgharị ahụ na-atụgharị gaa n'aka nri, na-egosi na a naghị emepụta ike axial n'okpuru ọnọdụ na bolt nwere ụfọdụ elongation, ma ọ bụ ike axial dị nnọọ ntakịrị, nke ya na ya na-agbanyeghi ihe mkpuchi ahụ megide ihe mmetụta axial. Mgbatị, o doro anya na elongation nke bolt n'oge a bụ elongation ụgha, ọ bụghị ezigbo elongation. Ihe kpatara elongation ụgha bụ na okpomọkụ nke na-eme ka ọkpụkpụ na-ekpuchi onwe ya n'oge usoro ikuku na-eme ka ọ dịkwuo mma na-emetụta mgbasa nke ebili mmiri ultrasonic, nke a na-egosipụta na ntụgharị. Ọ na-egosi na bolt e elongated, na-egosi na okpomọkụ nwere mmetụta na ultrasonic ife efe. Maka eserese 6, a na-ejikwa nut na-ekpochi onwe ya mee ihe maka nhazi, ma ihe kpatara na usoro nhazi adịghị agbanwe n'aka nri bụ na ọ bụ ezie na enwere esemokwu mgbe ị na-agbanye na nut na-ekpuchi onwe ya, a na-emepụta okpomọkụ, ma a na-etinye okpomọkụ na ndekọ nke ogologo mbụ nke bolt. A kpochapụrụ ya, na oge nhazi nke bolt dị mkpụmkpụ (na-abụkarị ihe na-erughị 5s), ya mere mmetụta nke okpomọkụ adịghị apụta na nhazi njirimara calibration.

Enwere ike ịhụ site na nyocha dị n'elu na esemokwu eri na ikuku ikuku na-eme ka ikpo ọkụ na-ebuli elu, nke na-ebelata ọsọ ọsọ ultrasonic, bụ nke a na-egosipụta dị ka ngbanwe yiri nke ntụgharị calibration n'aka nri. Torque, nke abụọ na-adabere na okpomọkụ na-emepụta site na esemokwu eri, dị ka e gosiri na Figure 10. Na Tebụl 2, a na-agụta ịdị ukwuu nke ngbanwe ziri ezi nke ntụgharị calibration na mmụba okpomọkụ nke bolt n'oge usoro nkwụsịtụ dum. Enwere ike ịhụ na ịdị ukwuu nke ngbanwe ziri ezi nke ngbanwe nhazi na-adaba na ogo nke mmụba okpomọkụ, ma nwee mmekọrịta dị n'usoro. Ọnụego ya dị ihe dịka 10.1. Na-eche na okpomọkụ na-abawanye site na 10 Celsius, ọdịiche oge ụda na-abawanye site na 101ns, kwekọrọ na ike axial nke 24.4kN na M12 bolt calibration curve. Site n'echiche anụ ahụ, a na-akọwa na mmụba nke okpomọkụ ga-eme ka ihe onwunwe resonant nke ihe mkpuchi ahụ gbanwee, nke mere na ultrasonic ebili mmiri na-agba ọsọ site na mgbanwe mgbanwe mgbanwe wee na-emetụta oge mgbasa ultrasonic.

4. Aro

Mgbe eji nkịtị aku naaku na-ekpochi onwe yaiji megharia njirimara njirimara nke bolt, a ga-enweta akụkụ dị iche iche nke calibration n'ihi ụzọ dị iche iche. The tightening torque nke onwe-kpọchi nut na-amụba okpomọkụ nke bolt, nke na-eme ka ultrasonic oge dị iche iche, na enwetara calibration àgwà usoro ga-agbanwe gaa n'aka nri na yiri.

N'oge ule ụlọ nyocha, a ga-ewepụ mmetụta nke okpomọkụ na ebili mmiri ultrasonic dị ka o kwere mee, ma ọ bụ otu usoro nhazi ahụ kwesịrị ịnakwere na usoro abụọ nke bolt calibration na axial force test.

Oge nzipu: Ọktoba 19-2022